Jan 30:

Reactor Core Isolation Cooling (RCIC) System

The RCIC is used in BWR-3 through BWR-6 boiling water reactor designs. The RCIC system is a single train standby system for safe shut down of the plant. The system is not considered part of the emergency core cooling system (ECCS), and does not have a loss of coolant accident (LOCA) function. The RCIC system is designed to ensure that sufficient reactor water inventory is maintained in the vessel to permit adequate core cooling. This prevents the reactor fuel from overheating in the event that the reactor is isolated from the secondary plant.

Following a normal reactor shut down, core fission product decay heat causes steam generation to continue, albeit at a reduced rate. During this time, the turbine bypass system diverts the steam to the main condenser if the reactor is not isolated from the secondary plant, or to the suppression pool through operation of safety/relief valves (SRVs) if the reactor is isolated.

The RCIC system supplies the makeup water required to maintain reactor vessel inventory. The turbine-driven pump supplies makeup water from the condensate storage tank (CST) to the reactor vessel. An alternate source of water is available from the suppression pool. The turbine is driven by a portion of the steam generated by the decay heat and exhausts to the suppression pool. This operation continues until the vessel pressure and temperature is reduced to the point that the residual heat removal (RHR) system can be placed into operation.First, I documented I predicted a LOOP...think I am the first person who ever predicted a extremely rare Loss Of Offsite Power accident and then it occurred.

I believe so far the important inop component are.

1) HPCI

2) LOOP

3) Four ADS/SRV since 2011

I think the plant is going to get a special inspection and maybe a Augment inspection. It might get raised to a red level finding...national implications.

I believe the smaller shutdown off site line, it wasn't safety qualified, bet you they were afraid to test it with a load it was so fragile.

So it scrammed at 52% power.

PRELIMINARY NOTIFICATION OF EVENT OR UNUSUAL OCCURRENCE - PNO-I-15-001

This preliminary notification constitutes EARLY notice of events of POSSIBLE safety or public

interest significance. Some of the information may not yet be fully verified or evaluated by the

Region I staff.

Facility Licensee Emergency Classification

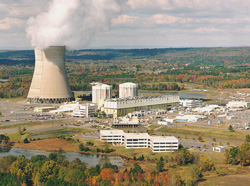

Entergy Nuclear Operations, Inc. __ Notification of Unusual Event

Pilgrim Nuclear Power Station ___ Alert

Plymouth, MA ___ Site Area Emergency

Docket No. 50-293 ___ General Emergency

License No. DPR-35 X Not Applicable

SUBJECT: PILGRIM NUCLEAR POWER STATION: SHUTDOWN GREATER THAN 72 HOURS DUE TO REACTOR SCRAM FOLLOWING A PARTIAL LOSS OF OFFSITE POWER

On January 27, 2015, Pilgrim Nuclear Power Station experienced an automatic scram following a turbine trip due to a partial loss of offsite power. The station was experiencing high winds and heavy snowfall during a severe winter storm when the station began experiencing degrading switchyard conditions. The station had already transferred the emergency busses onto their respective emergency diesel generators and was downpowering to 20% power to take the turbine offline. At 4:02 a.m. with the reactor at 52% power, the second offsite line was lost and the station experienced a load reject.

The station experienced equipment issues while cooling down after the scram including: the station diesel air compressor failed to start, one of four safety relief valves could not be operated manually from the control room, and high pressure coolant injection had to be secured due to failure of the gland seal motor.

The station is currently in cold shutdown, the safety buses are being powered by their respective emergency diesel generators, and all safety-related equipment required for safe plant shutdown are available. The licensee is working on restoring their 345kV lines.

Resident inspectors and region-based inspectors are providing oversight and performing

follow-up inspections.

This preliminary notification is issued for information only. The information presented herein has been discussed with the licensee and is current as of 1:00 p.m. on January 29, 2015. Commonwealth of Massachusetts officials have been kept informed.Nobody considers the 23 kilo-volt a legitimate safety line. You get it, they use it and it trips, that is proof it is a pure LOOP. As I said, they are preserving the operability of the 23 kilo-volt line just to mitigate the violation coming out of this. Or to conn the public that the grid was still connected to the plant.

One of two 345-kilovolt offsite lines was deenergized due to weather concerns. At about 52 percent power, the second 345-kilovolt line that provides off-site power to the plant tripped, resulting in a reactor shutdown, or scram, at about 4 a.m. (Nuclear power plants not only generate power and send it to the grid, they also receive a certain amount of power from the grid for operational purposes.)

A third off-site power line, a 23-kilovolt line, remains available. However, the emergency diesel generators for now remain the primary source of power for safety systems. The reactor was safely shut down, with plant safety systems performing as expected. The exact cause of the loss of the 345-KV power lines is still being investigated.The moderator has indicated they moved my article ..they have taken notice of my title of "From the Hands of God." The blizzard has stuck overnight and we are getting indications of the plant trip and LOOP. This God thing is me indicating I think this is a big deal and I got people talking to me. This NRC at the below is indication they added the next blog article about the new NRC inspection just for me.

Moderator January 28, 2015 at 9:53 am

"From the hands of God"

How many individuals in the USA ever predicted a LOOP at a specific plant at a particular timeframe and had the prediction openly documented on the internet two days before it happened? I think I am the first?

“Historic Blizzard Juno Warning Going Over Pilgrim Nuclear Plant”Just for me:

The implications of the LOOP, plant trip and components degradation are hitting me...there has been no public discussions about the failed SRV valve as of yet. I know the SRV valve didn't work and I am hinting to the NRC pretty heavy I am into the details with the history of the SRVs.Additional Scrutiny at Pilgrim Nuclear Power Plant Set to Continue

Posted by on January 28, 2015Neil Sheehan

Public Affairs Officer

Region I

Last fall, a team of NRC inspectors was tasked with evaluating whether issues at the Pilgrim nuclear power plant that triggered increased agency oversight had been satisfactorily addressed. That team has now returned its findings in the form of a newly issued inspection report.

And the answer – at least at this point in time – is that Entergy, the Plymouth, Mass., plant’s owner, still has some more work to do.

- Mike MulliganJanuary 28, 2015 at 11:18 am

Does Scrutiny ever lead to a behavior change with a licensee? Why didn’t it work from this new inspection report preventing the plant trip and newest in storm Juno LOOP. Ring that up you cash register risk perspectives with a broken HPCI and 55 LOOPs per one hundred years.

Makes me laugh…have to wait until pilgrim is ready to receive the inspection?

Maybe if the inspection was more timelier to the 2013 events…Pilgrim wouldn't have had the yesterday’s LOOP. How come the NRC didn’t force Pilgrim to shut down prior to storm Juno as identified in the new inspection report, as their switchyard and the outside transmission system was so fragile for the expected climate and especially winter storms.

We knew Pilgrim was going down the tubes being in 2011 when they accepted poor quality brand new SRVs (all four of them)…the pathetic host of leaks, down powers and shutdowns over this new equipment. We were shocked the agency would treat these important last ditch core cooling components so cavalierly. You know how I feel, read my 2.206s. I contend if the agency would have slapped Entergy hard in the head with a big fine or prolonged shutdown then… you would have woke Entergy up from their nap. Then Pilgrim would have sailed through storm Juno uneventful at 100% power.

I call the NRC a “paper cut” regulator….the only power they got over these giant companies as incentive to get their heads on straight is to give them one insignificant paper cut after another to no results.

Why is the NRC allowing our NE grid to become so fragile? Why is the two plant Millstone (Dominion) unit and Pilgrim (Entergy) going down the tubes together…why can’t the agency control these plants? I think it extremely dangerous to allow a plant to be operating in “organizational dysfunction” and impaired “safety culture” mode knowingly for prolong periods of time: repetitively spewing out of the plants safety component breakdown, unseen component degradation and showing contempt towards the agency with knowingly violating tech specs, licensing conditions and the USFARs. It is like operating your car carelessly with the low oil pressure red warning light for days and weeks. I think it is in the greater interest of the United State of American to drive a plant early and quickly out of disorder and chaotic organizational conditions?

The NRC talking to me again. The USFAR don't cover ever aspect of a plant condition. The current state of the organization, the condition of the equipment and how the plant in the past responded to to similar problems...the conditions expressed by the NRC itself in the new inspection. The NRC recently has stated they take it very seriously when a plant keeps challenging and testing needlessly it safety systems. It is a very dangerous practice and it wears out the gear. You just can't keep testing your plant safety components...putting or turning a safety response into the normal operating regime of a plant. Because switchyard and transmission component are't reliable and causing plant trips and deep safety challenge...you can't explain this as the normal and expected operational events.

Nuclear Power Plants Ready For Major Winter Storm

Posted by on January 26, 2015

Then this:

Additional Scrutiny at Pilgrim Nuclear Power Plant Set to Continue

Posted by on January 28, 2015

Neil Sheehan

Public Affairs Officer

Region IHere I am laying out why this needs a Special or Augmented inspection...the failed components and I am giving the NRC deep details with the operational problems documented in the docket. I giving them the short story documented in the docket with why I think all ADS and SRV valves are not operable based on the cumulative recent operating experiences and agency documents. They all know this story is tracking with all the documents.

- Mike MulliganJanuary 29, 2015 at 7:10 pmYour comment is awaiting moderation.

- So when you sending the special inspection team? An augment inspection?

Sound like I had a little birdy whispering in my ears?

Just when you could think the repetitive TDAFWP couldn’t get any worst at Millstone…now we got the poor quality SRVs failing over and over again at Pilgrim for 4 years just like the TDAFW pumps did. Is this going to take three special inspection to fix just like Millstone? Wait, this is like the TDAFWP and both half capabilities electric aux feed water pumps being simultaneously inop for 4 years. You should conservatively call “all” the SRVs/ADS valves inop and not according to tech specs since 2011.

I bet you the SRV was leaking for a prolonged period of time and the agency hid it on us. The hide the leak philosophy first, before fix it quickly philosophy.This caused the valve to fail.The ADS/ SRV valves were inop since 2011 when first installed. Before they even got warmed they were inop. You get it, after “new” installation of the “new” three stage SRVs (4 of them), the first leak impairing the operation of one of these valve occurred within one or two months. Maybe within weeks of first start-up. This situation is unprecedented in the nuclear industry. I’ll bet you we are heading to a cover-up of a red finding. This is not about one valve…the whole group of them have a design defect and uncontrollable poor quality components from day one. A common mode failure of the automatic depressurization system and safety relief valve for four years. These nuclear safety valves weren’t fit to be in nuclear power plant.

(Yesterday) “We knew Pilgrim was going down the tubes beginning in 2011 when they accepted poor quality brand new SRVs (all four of them)…the pathetic host of leaks, down powers and shutdowns over this new equipment. We were shocked the agency would treat these important last ditch core cooling components so cavalierly.”

We have had a dangerous meltdown of the effectiveness of the NRC. i am writing up a 2.206 requesting the Pilgrim plant remain shutdown. All plants in Region I should be shutdown because there was such a severe breakdown in the NRC.

What level of risk would that get you to: HPIC inop, SRV/ads inop, in a LOOP and the risk of 55 loops per 100 years (52 more LOOPs than assumed in calculations)? I think this is the most severe accident we have had in a long time.

“The station experienced equipment issues while cooling down after the scram including: the

station diesel air compressor failed to start, one of four safety relief valves could not be operated

manually from the control room, and high pressure coolant injection had to be secured due to

failure of the gland seal motor.”

I think the small transmission line is just a shame...going to be used as risk mitigation strategy for the violation. It is going to have great worth in calculating the violation level, but absolutely no worth for the operators in house. It just doesn't have the redundancy or the proper safety quality to be use as a source of power in nuclear plant.

The mysteriously discovered third line leading to a partial LOOP is nothing but regulator and licencee fraud...they ginned it up just to reduce the violation level. The 23 kilo-volt line is never mention in any of the new inspection report LOOPs...whether it was energized or not. The recent inspection report treats the plant as only having two viable lines into the plant. I find it highly suspicious now they are talking about partial LOOPs.

The mysteriously discovered third line leading to a partial LOOP is nothing but regulator and licencee fraud...they ginned it up just to reduce the violation level. The 23 kilo-volt line is never mention in any of the new inspection report LOOPs...whether it was energized or not. The recent inspection report treats the plant as only having two viable lines into the plant. I find it highly suspicious now they are talking about partial LOOPs.

Complicated Reactor Scram due to Loss of Offsite Power on October 14, 2013 Entergy assembled a multi-discipline team to perform the RCE for this issue. In addition to the direct cause of the failure of a defective pole at an offsite substation, which was determined to be outside the control of Entergy, the RCE documented one root and one contributing cause:

Entergy failed to ensure that station procedures contained adequate pre-defined, risk-based criteria for planned maintenance on offsite transmission equipment which places Pilgrim in an SPV to an automatic scram (Root Cause); and

The design for generation at Pilgrim is less than robust, with only two paths for generation output and offsite power supply (Contributing Cause).

“This got to be an act of god: A blizzard that knocks Pilgrim off the grid on Jan 27 and this below inspection report is dated on Jan 26. It explains why Pilgrim has so many LOOPS and why the NRC remains inconsequential with controlling bad actor licensees. I yet can’t get a copiable document…have to wait till it gets on Adams.

‘Pilgrim Nuclear Power Station – NRC 95002 Supplemental Inspection Report 05000293/2014008 and Assignment of Two Parallel White Performance Indicator Inspection Findings’

Did the agency see the blizzard coming in anticipation of the LOOP and decided it has to be released the IR yesterday! This is proof the agency seen the LOOP coming and didn’t force Pilgrim to shutdown prior to the storm. They should have ordered Pilgrim to shutdown 4 hours before the blizzard hit. This would have more caused them incentive to repair their fleet wide nuclear endeavors. It would have been invaluable for all the rest of the utilities to see.

If you were god, would your release Pilgrim’s inspection report before the LOOP or after the LOOP?

This is my proof that an intelligent god exist!!! I never needed any proof.

Bill, why haven’t you put your hat in ring to be a NRC commissioner?

I have to give “great” credit to the NRC for publishing my items! Thank you Victor.

steamshovel2002@yahoo.com

Note: Moved by the moderator