So basically ANO and Entergy got three yellow findings.

January 22, 2015 SUBJECT: ARKANSAS NUCLEAR ONE, UNITS 1 AND 2 - FINAL SIGNIFICANCE DETERMINATION OF YELLOW FINDING AND NOTICE OF VIOLATION; NRC INSPECTION REPORT 05000313/2014010 AND 05000368/2014010Above all else, these flooding problems weren't discovered by an effective process of Entergy and the NRC. I bet you effectively Entergy is paying the dead and injured employees mere pennies in compensation and punishment. After all, it Arkansas you know. It took Entergy not following procedures and then dropping a 550 ton stator killing a employee to uncover the flooding flaws. The punishment levels get derived through a grossly politically assumption system...perceived through a process and calculation system nobody understands. Nobody gets a penalty or punishment including the NRC for not having a effective organization before the stator dropped. Nobody got fired here or gone to jail. They are just paper whipping the violation. Both these plants should have paid the price of the plants being prohibited from starting up for a year or two.

It got to be noted, as you go down the emergency operating procedures the complexity massively increases and they increasingly depend on less quality components and procedures. Complexity and uncertainty levels just skyrockets as you increasingly depend on not fully designed and engineered systems and procedures. At some level of complexity and stress, an outcome can never be assured. As the accident strips massively the redundant safety systems away from the plant, the consequence of a error drastically increase the risk of damaging the core. I hate add on systems or component because usually they aren't fully tested and all the uncertainties aren't fully washed out. I like a holistically designed plant...all these components in on plant first design.

The NRC take on these cooling paths to be valid should be, you have to demonstrate flow up to the first containment isolation valve. If you depend on service water flow or temporally diesel generator, then you have to demonstrate flow up to the first containment isolation valve and you measure flow and pressure. Make believe flow paths are not approved. You really need periodic, yearly or every two years...the troops getting on the ground and pressurizing the alignment up to the first isolation valve to be even considered as a safety system.

Basically in this day and age, a double fail safe, push a button and the system aligns and fills up and SG level is controlled...

This is basically the Fukushima dilemma...not having a diesel generator 100 feet up the ocean bluff and hard wired to the plant. The philosophy with the Japanese in a Tsunami, of having to fight the battle to save the plant in the flood waters within the plant.

So how about a big tank way outside the flood zone. It hard piped into the plant right up to the steam generators. Starting the diesel generator, push a button and open up and valve or two...everyone safe. An access road to the tank...with the fire department cycling their trucks in a out to fill the tank. You could have constructed a sturdy cement cauldron out in the river and hard piped to near this tank. Then a fire truck could continuously fill the tank from the river.

Then the other Japanese dilemma...would you damage the steam generator in order to cool the core.

I didn't hear about the flex system coming in to save Entergy's butts.A not recognized risk, if the staff and licensed operators think the mitigating strategies or flow paths are too star treky(not believable)...it is going to impact the safety culture. I'd like to see if the licensed operators accept the cooling paths.

Basically risk perspectives is a Abracadabra campaign monied system where the NRC and Entergy go into dark smoke filled rooms to negotiate a paper cut punishment and violation.

You get it, the community has no say in it.

So why isn’t the NRC recalculating the so call electrical yellow finding violation. It seems the flooding yellow finding was active just prior to the first yellow finding. Two cases:

1) ANO stator electrical yellow finding with the flooding barriers all according to regulations.

2) ANO stator electrical yellow finding with the flooding barriers according to an inadequate flooding barrier in this second ANO yellow finding.

Once can legitimately surmise the second example contains a lot more risk than the first example, and justified a lot bigger violation.

This would be my contention that the disposition of risk perspective is riddled with fraud and corruption.

The flooding issue is another example with inspector activities and the ROP is severely inadequate to know the true conditions at a power plant…the NRC selectively enforces tech specs and the licensing conditions at these power Plants. Why isn’t it a slam dunk that ANO employees are going to jail? Why isn’t there some serious soul searching going on in the NRC with why their inspection and inspector activities didn’t undercover these violation at the first opportunity many years and decades ago?

*I am looking for this answer: What is the generic “Loss of offsite power” accident rate used in all NRC risk calculation and within coming up with a plant violation level? I am told it is 2, 3 or 5 LOOPs per 100 years. Could the answer be in the once per hundred year terms?Mike MulliganHinsdale, NH

NRC Finalizes Violations for Arkansas Nuclear One

Posted by on January 23, 2015

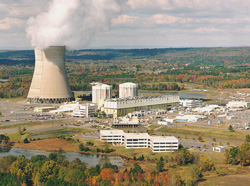

The Arkansas Nuclear One power plant, in Russellville, Ark., is coming under increased NRC focus as a result of flood protection problems.

Beginning in 2013, Entergy Operations officials and the NRC began extensive inspections of the flood protection program at ANO. Many problems were discovered and are described in a Sept. 9, 2014, NRC inspection report.

All told, more than 100 previously unknown flood barrier deficiencies creating flooding pathways into the site’s two auxiliary buildings were found. These included defective floor seals, flooding barriers that were designed, but never installed, and seals that had deteriorated over time. In one case, a special hatch that was supposed to be close a ventilation duct in the Unit 1 auxiliary building in the event of flooding had never been installed.

In the unlikely event of extreme flooding – a kind not seen since weather records have been kept for the area – significant amounts of water could have entered the auxiliary buildings. This could have submerged vital plant equipment, as well as the emergency diesel generator fuel vaults. The licensee has replaced degraded seals, installed new flood barriers and adopted new measures to better protect the site from flooding.

NRC held a regulatory conference with Entergy officials on Oct. 28, 2014. After considering information provided by the company, NRC determined violations related to flood protection have substantial safety significance, or are “yellow.” (The NRC evaluates regulatory performance at nuclear plants with a color coded process that classifies inspection findings as green, white, yellow or red, in order of increasing safety significance.)

The NRC divides plants into five performance categories, or columns on its Action Matrix. ANO Units 1 and 2 received yellow violations in June 2014 because electrical equipment damaged during an industrial incident increased risk to the plant. Workers were moving a 525-ton component out of the plant’s turbine building when a temporary lifting rig collapsed on March 13, 2013, damaging plant equipment. Those violations moved both units from Column 1 to Column 3 of the NRC’s Action Matrix. The agency increases its oversight of plants as performance declines.

The new violations will lead NRC to reassess whether even more inspection resources need to be focused on ANO. The NRC will determine the appropriate level of agency oversight and notify Entergy officials of that decision in a separate letter.

No comments:

Post a Comment